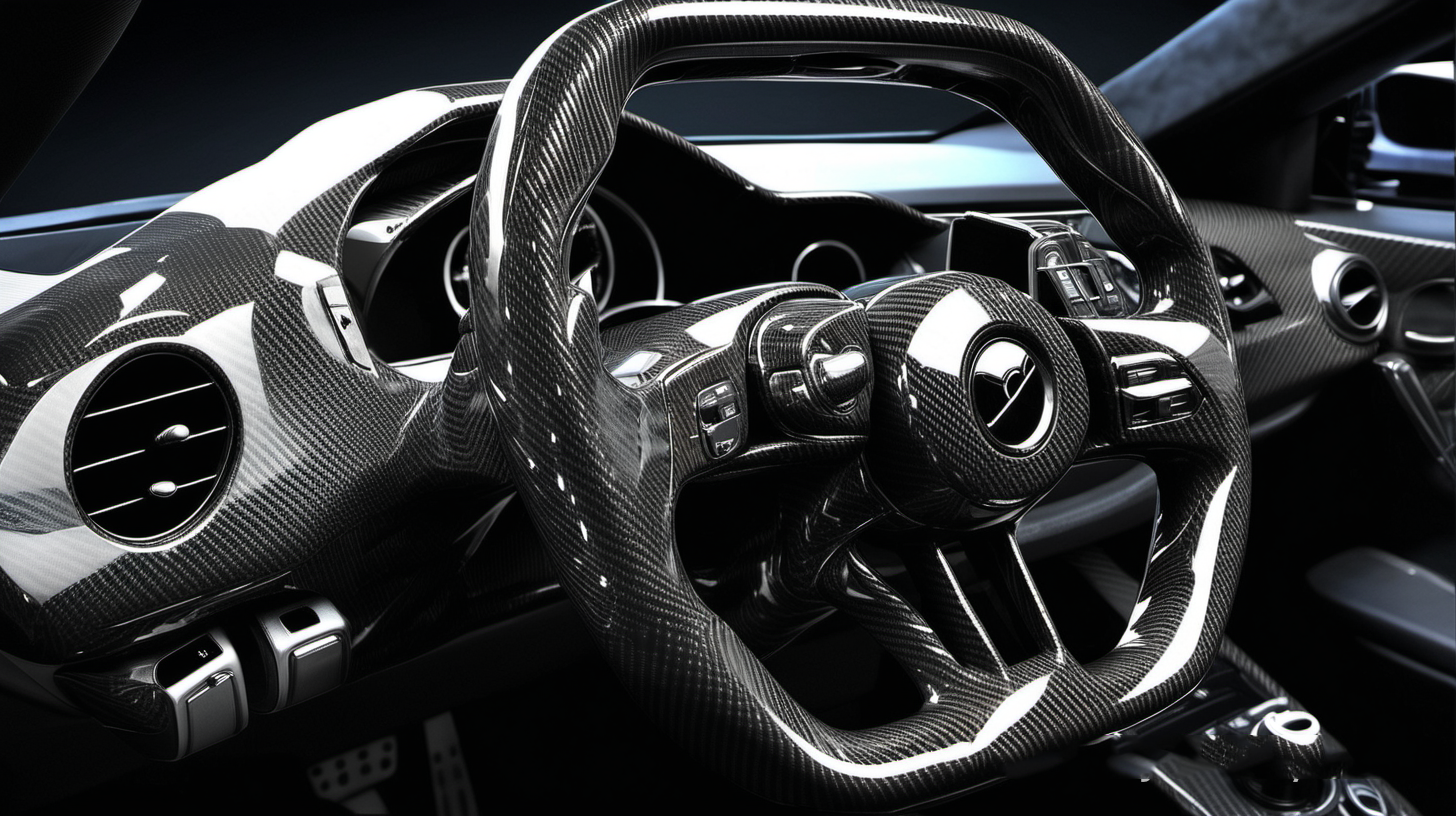

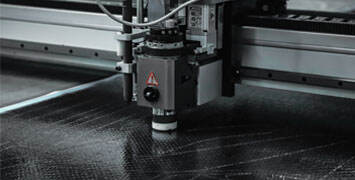

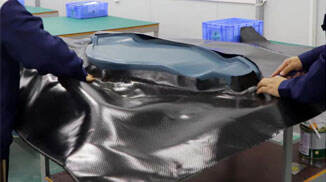

The surge in demand for weight reduction in the automotive industry, driven by

required engine efficiency measures and the adoption of electrification, has

underscored the importance of cost-efficient lightweight solutions. Leveraging new

developments in processes and materials, there is now a broad scope for high-volume

applications of fiber composite materials, especially in the manufacturing of carbon

fiber interior parts. This optimization caters to the need for efficient and economica

solutions in enhancing both performance and aesthetics within the vehicle's interior.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

IS

IS

LA

LA