COMPOSITE LAYUP PROCESS

The composite layup process is a technique used to manufacture composite parts, such as those made from carbon fiber, fiberglass, or Kevlar. It involves laying up layers of reinforcing fibers and resin in a mold to create the desired shape and properties.

It offers flexibility in design and material selection, making it suitable for a wide range of applications across various industries, including aerospace, automotive, marine, and sporting goods.

Open Mould Processes:

Open mold processes are widely used in composite fabrication, offering flexibility and ease of use. Two standard methods in open mold processes are hand layup and spray-up composites.

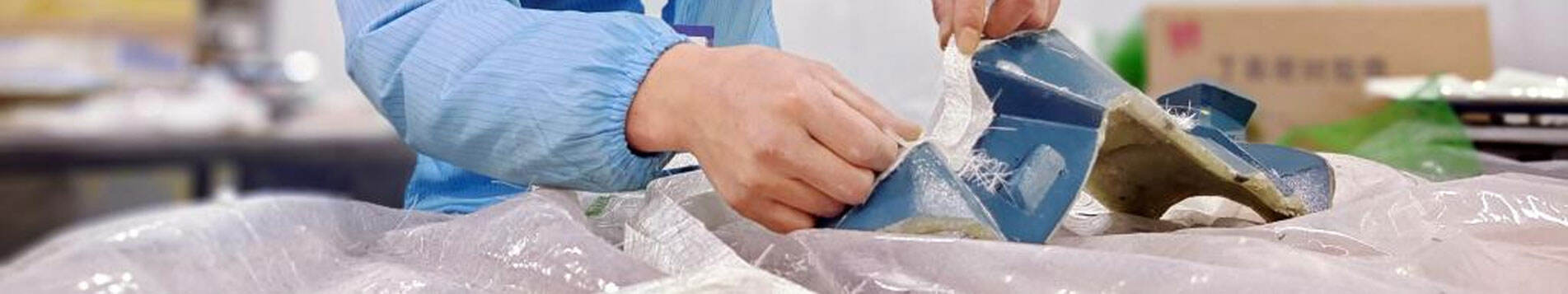

Hand Layup Composites:

Hand layup is a traditional and widely used method for fabricating composite parts. It involves manually placing layers of reinforcing fibers, such as carbon or fiberglass, into a mold and saturating them with a matrix material, typically a resin. This process requires skilled labor, precision, and attention to detail to ensure proper fiber alignment and resin distribution.

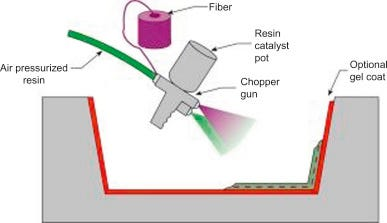

Spray-Up Composites:

Spray-up composites, or chopped strand spray-up, involve spraying a mixture of chopped fibers and resin onto an open mold using specialized equipment. The fibers and resin are sprayed onto the mold surface, creating a homogeneous layer. This method allows for quick production of large and complex shapes.

Prep Pegging Processes:

Prepregging is a widely used method that involves impregnating reinforcement fibers with resin in a controlled environment. The resulting material, called a prepreg, is a semi-finished product that can be used in various composite fabrication processes.

Automated Fiber Placement (AFP) and Automated Tape Laying (ATL):

These advanced techniques utilize robotic systems to lay down prepreg materials in specific orientations and patterns. AFP involves precisely positioning and placing continuous fibers onto a mold or tool, while ATL uses automated machinery to lay down continuous fiber tapes. These processes ensure precise fiber placement, producing high-quality composite parts with optimized structural performance.

Autoclave Molding:

Autoclave molding is a high-pressure and high-temperature process used for advanced composites. It involves placing a layup of prepreg materials into a mold and subjecting it to elevated pressure and heat inside an autoclave. This process allows for the consolidation and curing of composite parts, resulting in exceptional strength and surface finish.

Sheet Molding Compound (SMC):

Sheet molding compound is a semi-finished composite material consisting of chopped fibers, thermosetting resin, and additives. It is compression molded at elevated temperatures and pressures to produce complex parts with excellent strength and surface finish. SMC is widely used in the automotive, construction, and electrical industries.

Thermoplastic Molding:

Thermoplastic composites utilize thermoplastic matrix materials that can be melted and reformed multiple times. Injection molding is commonly used in thermoplastic molding, where the thermoplastic matrix is melted and injected into a mold. Upon cooling, it solidifies and takes the shape of the mold, forming the desired composite part.

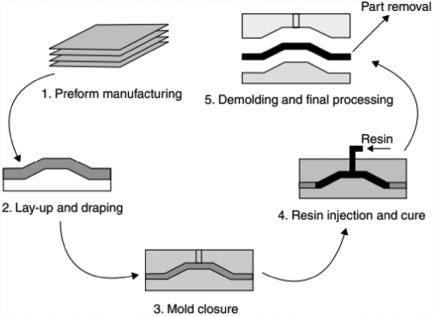

Resin Transfer Molding (RTM):

RTM is a closed-mold process that involves injecting liquid resin into a pre-formed cavity containing dry fibers. The resin is forced into the mold under pressure, impregnating the fibers and filling the cavity. RTM allows for precise control over resin flow, resulting in consistent part quality and reduced void content.

Filament Winding Process:

Filament winding is a specialized process to create composite structures with high strength-to-weight ratios, such as pipes, pressure vessels, and rocket motor casings. It involves the precise winding of continuous fibers, such as carbon or glass, onto a rotating mandrel in a specific pattern. The fibers are impregnated with resin during winding or post-winding, creating a strong and lightweight composite structure.

Pultrusion Process:

Pultrusion is a continuous manufacturing process that produces profiles with a constant cross-section. In this process, reinforcement fibers, such as carbon or fiberglass, are saturated with resin and pulled through a heated die. The die shapes the composite profile, and as it passes through the die, the resin cures, resulting in a continuous composite part with high fiber content and excellent mechanical properties.

The world of composite fabrication encompasses a wide range of processes, each with its own advantages and applications. From traditional hand layup to advanced automated methods and 3D printing, these fabrication techniques enable the creation of strong, lightweight, and tailored composite materials for various industries.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

IS

IS

LA

LA